Custom pipe spools play a crucial role in various industries, serving as essential components for connecting different parts of pipelines. Industries such as oil and gas, chemical, and power generation rely on these pipe spools to ensure the efficient and safe transport of fluids. Nickel alloy fabrication, along with the expertise of custom pipe spools fabricators and custom-machined fasteners, forms the foundation of these essential components.

The Significance of Nickel Alloy Fabrication

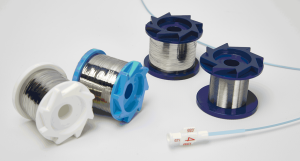

It stands as a cornerstone in the creation of reliable custom pipe spools. Nickel alloys possess exceptional properties that make them ideal for demanding environments. These properties include corrosion resistance, high-temperature stability, and strength. Nickel alloy fabrication involves shaping these materials into the required pipe spool forms, ensuring longevity and performance in challenging operational conditions.

Role of Custom Pipe Spools Fabricators

Custom pipe spool fabricators are skilled professionals responsible for turning raw materials, like nickel alloys, into functional pipe spools. Their expertise lies in understanding the specific needs of different industries and creating spools that meet those requirements. Here’s how custom pipe spool fabricators contribute to success:

- Material Selection: Fabricators choose the appropriate nickel alloy based on factors such as the fluid being transported, temperature, pressure, and corrosion potential.

- Precision Fabrication: They employ advanced techniques to cut, shape, and weld the nickel alloy accurately, ensuring that the resulting pipe spools fit seamlessly into the existing infrastructure.

- Quality Assurance: Customized pipe spools fabricatorsconduct rigorous quality checks throughout the fabrication process to identify and rectify any defects, ensuring the final product’s reliability.

- Adherence to Standards: Fabricators ensure that the custom pipe spools meet industry standards and regulations, guaranteeing safe and compliant installations.

Custom Machined Fasteners: Bolstering Reliability

The integrity of custom pipe spools depends not only on the fabrication process but also on the connections that hold them together. Custom machined fasteners play a vital role in maintaining the structural soundness of these pipe spools. These fasteners are tailored to the specific requirements of each pipe spool, enhancing their reliability and longevity.

- Tailored Strength: Customized machined fasteners are designed to provide the precise level of clamping force needed to secure pipe spools without compromising their integrity.

- Corrosion Resistance: Just like the nickel alloys used in the pipe spools, these fasteners are often made from materials that resist corrosion, ensuring they remain effective even in harsh conditions.

- Perfect Fit: Fasteners are machined with precision to ensure they fit perfectly into the designated spots, reducing the risk of leaks and other failures.

- Collaboration with Fabricators: Custom-machined fastener manufacturers work closely with custom pipe spools fabricators to create a unified, reliable system.

Connecting for Success

The collaboration between nickel alloy production experts, customized pipe spool fabricators, and custom-machined fastener manufacturers culminates in a system that forms the backbone of various industries. Custom pipe spools, made possible by the expertise of these professionals, ensure the safe and efficient transport of fluids while minimizing downtime and maintenance costs. The success of industries such as oil and gas, chemical, and power generation hinges on these seemingly small yet critically important components.

Final Remarks:

Custom pipe spools might not always be the most visible elements in industrial setups, but they are undoubtedly among the most crucial. Through the combination of nickel alloy fabrication, the skills of custom pipe spools fabricators, and the reliability of custom-machined fasteners, these unassuming components play a vital role in maintaining seamless operations across industries. Recognizing their significance and investing in their quality is a direct investment in the long-term success and sustainability of industrial endeavors.