With the rate of industrialization at all times high, employers at all levels worldwide should make the safety of their workers an indispensable requirement. And no other place is workplace safety more relevant than in areas where high voltage electricity is the primary energy source; the dangers are all around.

This article discusses the various aspects of electrical arc flash safety, which revolve around personnel training, maintenance, and preventive measures concerning risk management strategies designed for the protection of employees and compliance with regulations.

By exploring these elements, we can point out the importance of the overall safety framework applicable in organizations that not only safeguards employees but also shapes the safety culture among the employees.

Electrical Safety Training

Electrical safety training is the first step toward building a company safety culture. Initiatives like NFPA 70E arc flash training for Qualified Workers help train employees to handle electrical equipment safely. From hazard identification to enforcing appropriate safety protocols, these training sessions teach workers about reducing risks and responding appropriately to electrical hazards.

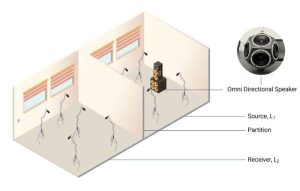

Arc Flash Studies

Electrical arc flash analysis, performed using the IEEE 1584 standard’s calculations, provides valuable insights for recognizing and curbing electrical hazards. Such analysis provides critical information on incident energy results, which organizations can use to implement timely preventive actions.

By labeling electrical panels based on these discoveries, businesses ensure their employees know of those risks and are empowered to undertake preventive measures to keep themselves safe.

Electrical Preventive Maintenance

Prevention of risks is a key aspect of a reliable electrical safety management system. Regular inspections, equipment cataloging, and labeling according to industry standards are the key elements of a preventive maintenance program.

Organizations will be able to avoid electrical hazards by knowing and taking care of them before they exceed measures, and this will ensure that they have reliable equipment, making their operation safer and more efficient.

Change Management

Dynamic change management is valuable for maintaining electrical safety standards in dynamic work situations. The facilities are ever-evolving; thus, adaptable solutions are introduced regularly to uphold safety standards.

Adaptable labeling options with simplified change management practices help to effortlessly incorporate safety systems in workplaces as they continue to transform, thus ensuring safety remains the organization’s top priority amidst organizational changes.

Onsite Services

On-site services like training sessions, an electrical arc flash survey, and a maintenance review are necessary to improve worker safety. Through collaboration with experienced professionals, businesses can receive answers to their questions that deal with their particular needs or requirements.

It could be from conducting training sessions for the workers or carrying out the entire review of electrical installations; on-site operations always contribute so much to safe working environments.

Summary

Workplace safety is the key to workers’ protection, and following all the safety regulations is crucial in the industrial environment. Organizations should invest in extensive electrical safety training, arc flash studies, and preventive maintenance services to create a safer working environment and cultivate staff well-being and productivity. These initiatives, including knowledge of employees and preventive maintenance, are critical to keeping the industrial environment safe for employees.

Also Read: Securing Your Cryptocurrency Investments: Why MPC Wallets Matter