There are many concerns over the negative impacts of human activity on the planet. The threat of global warming and climate change are reasons for public panic. Another problem plaguing our world is pollution. Many industries trade their harmful processes for green solutions to counter environmental pollution. The industrial cleaning industry is an example of such.

Industrial cleaning often involves the use of substances with harmful waste products. If these end products are not well disposed of, they can cause severe complications to the earth. These concerns include air and soil pollution, water contamination, and potential health issues.

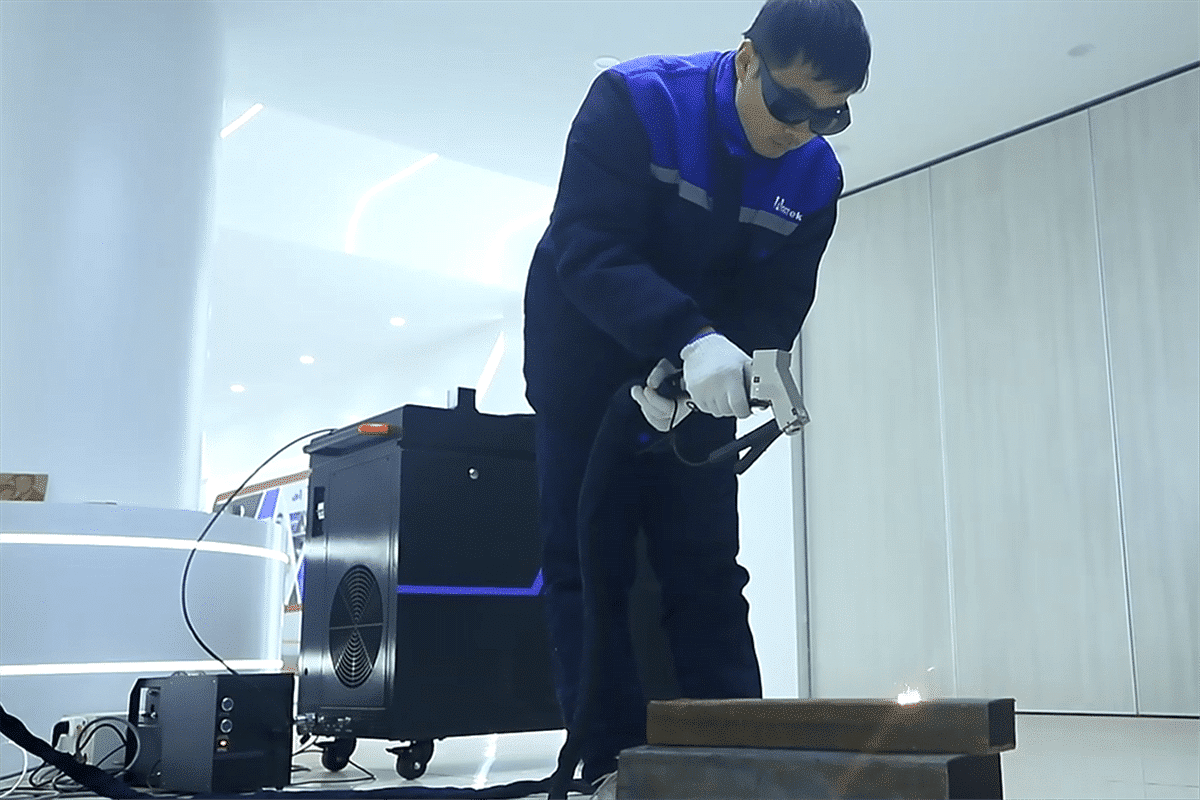

In response to these destructive outcomes, cleaning industries turn to laser cleaners. Laser cleaning machines are efficient and eco-friendly devices. They use concentrated laser beams to remove impurities from materials. Laser cleaning is also precise and non-contact in nature. These attributes make laser cleaners a popular option for many industrial applications.

This article will explore the environmental benefits of laser cleaning machines. We aim to highlight the key factors that make this technique a green option to other methods. If you need one, please check it.

Positive Impacts of Laser Cleaning on the Environment

1.Laser cleaning saves energy:

Modern laser systems save more energy since they use less power than other machines. Electricity and natural gases are the primary energy sources in the manufacturing industry. Not surprisingly, there is a heavy reliance on these consumables. But this reliance is akin to a toxic relationship because of the adverse effects that arise.

In contrast to most machines, laser cleaners use only 30% of electricity while in use.

Most traditional cleaning methods need plenty of power to run their processes. Yet, laser cleaning is the most efficient method and uses less than half of this energy. This unique trait helps operators save on costs and also prevent pollution.

2.Waste Elimination:

The absence of harmful end products is one of the most important benefits of laser cleaning. Most cleaning methods rely on the use of toxic chemicals for their applications. Unfortunately, they produce waste that places people and the environment at risk.

Laser cleaning, on the other hand, uses only electricity as a power source. This means no need for chemicals or excessive heat and energy. And because no chemicals are involved, toxic waste won’t be produced. So there is no chance of pollution or exposing workers to dangerous chemicals.

3.Safety and Health Benefits:

Unlike traditional cleaning methods, laser cleaning is gentle and hands-free. The unique non-contact approach of this technique reduces the risk of workplace accidents. This is because many cleaning methods rely on harsh chemicals and substances.

For example, sandblasting involves the use of high-pressure blasts of abrasive materials. This method can cause eye injuries, cuts, and respiratory problems from inhaling dust. Likewise, the agents used in chemical cleaning cause burns, irritation, and breathing difficulties.

In contrast, as there is no contact with the laser beam, there is almost no risk of workplace injury. These machines create a safe and healthy work environment for employees. They help companies avoid compensation costs and channel these expenses to other areas.

4.Cleaner Alternative:

Laser cleaning is an innovative technique that removes impurities without producing toxic waste. Unlike other methods, it eliminates the need for physical contact and aggressive materials. This results in minimal damage to the surface and protection against pollution.

Air and water pollution are the most common concerns in cleaning industries.

a. Air Pollution:

Sandblasting is a procedure that yields large amounts of dust and debris. The presence of these particles in the air causes breathing difficulties among workers. Although a laser cleaning tool generates dust after use, the amount is negligible. This allows workers to easily clean and dispose of the waste from the cleaning process. It thus prevents air pollution and provides workers with a safe working space.

b.Water Contamination:

Laser cleaning is a dehydrated process. It uses a laser beam to chip or flake off foreign matter from the surface of a material. Compared to water-dependent methods like power washing, lasers offer two main benefits. One is the conservation of water. The other is the prevention of run-offs into soil and water bodies.

Concluding Remarks

Laser cleaning machines give us hope in a world that fights to protect its environment. These machines are environment-conscious yet quick and efficient. The benefits they provide cut across different industries and applications. These machines offer real solutions to a problem that threatens the safety of our planet. Hence, they are ideal for companies searching for a greener approach.

Alas, using laser cleaning systems is not without its challenges. The main cons of a laser cleaning machine are its cost and accessibility. These machines are expensive, which makes them unavailable to businesses with tight budgets. But despite these limitations, these machines signify a step towards adopting renewable practices.